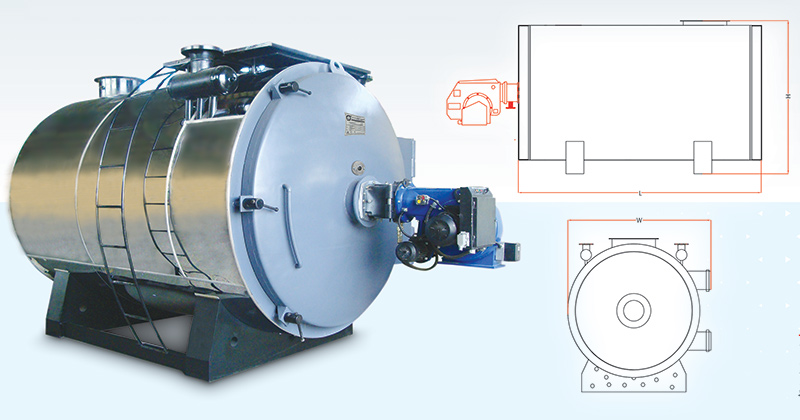

Hot oil boiler

In industrial heating systems, water and steam are used as the Heat transferring media. So producing steam at high temperatures requires increasing working pressure, which is not easy to achieve. Therefore, in the following industries, hot oil boilers are used for heat transfer:

Shipbuilding industries, Asphalt industries, crude oil heating and plastic industries. Because the hot oil boiler works up to 300 ° C at a pressure close to atmospheric pressure, while to achieve a temperature of 300 ° by water and steam we need a working pressure equal to 85 bar or use superheated steam (superheated steam is a heater that increases its temperature under constant pressure). In addition to being costly, superheated steam has a lower calorific value than hot oil under equal conditions.

In addition to other advantages of using hot oil as a working Heat transferring media instead of water and steam at high temperatures, the following can be mentioned:

. No sediment and corrosion

. No steam shocks and steam flashes

. No freezing when the device is off

. Less noise compared to boilers

Hot oil boiler

In industrial heating systems, water and steam are used as the Heat transferring media. So producing steam at high temperatures requires increasing working pressure, which is not easy to achieve. Therefore, in the following industries, hot oil boilers are used for heat transfer:

Shipbuilding industries, Asphalt industries, crude oil heating and plastic industries. Because the hot oil boiler works up to 300 ° C at a pressure close to atmospheric pressure, while to achieve a temperature of 300 ° by water and steam we need a working pressure equal to 85 bar or use superheated steam (superheated steam is a heater that increases its temperature under constant pressure). In addition to being costly, superheated steam has a lower calorific value than hot oil under equal conditions.

In addition to other advantages of using hot oil as a working Heat transferring media instead of water and steam at high temperatures, the following can be mentioned:

. No sediment and corrosion

. No steam shocks and steam flashes

. No freezing when the device is off

Benefits and technical specifications:

. The material consumed in all pressurized parts is 17MN4-DIN17155 and in the pipes used is 8.35 ST-17175 DIN.

. It is designed and manufactured according to the international standard DIN4754

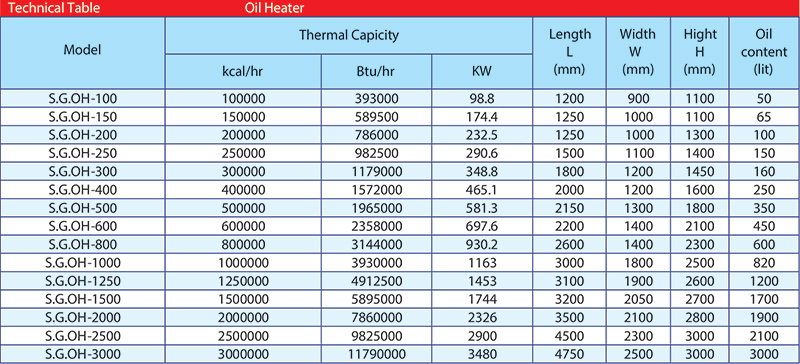

. Available in heat capacity of 100.0000-5000.000 kcal / hr

. All manufacturing operations under the direct supervision of quality control inspectors and performing pt, rt, ut and pneumatic testing of devices for 24 hours

. capability to operate up to 350° C (it is depends on the thermal oil)

. Easy to maintain and operate

. Insulation with ceramic fibers grade 1260 with density 128kg / m3 with a thickness of 100mm

. Use of very precise control equipment made in European countries

. Due to the unique design, the pressure drop in the oil path is very low and consequently the pumping cost is reduced.

. Possibility of installing a recuperator in the flue gas outlet path to preheat the combustion air to the burner and increase efficiency