U Type coil Heat Exchanger

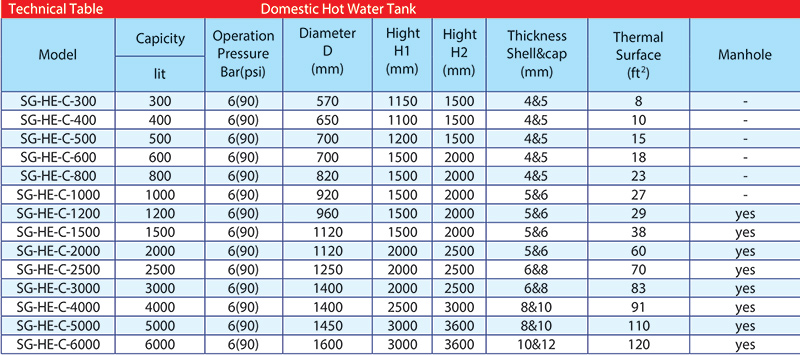

Domestic Hot Water Tank

The most common way to produce sanitary hot water and store water for hospitals, stadiums, hotels, apartments is to use a domestic hot water.

Domestic hot water include a tank equipped with two capes and one or more copper coils. The hot water or steam produced by the boiler passes through a heat coil and after exchanging heat with the wall of copper pipes, it leaves the coil. This heat exchange causes the copper pipe to heat and the cold water outside the pipe to heat up.

Water is used as the heat transfer media because water has a higher specific heat than the other media. That is, one kilogram of water can provide more heat than other media. The coil tank is made of galvanized sheet, but in case of using black sheet (higher pressures), the inside of the tanks are covered with epoxy coating. The thickness of the steel sheet used is also according to the working pressure, working temperature and water corrosion and according to the standard of tanks under Pressure is calculated. Based on the installation location, these tanks are used in two types, vertical and horizontal.

Technical specifications and benefits:

. Design and construction according to ASME standard

. The use of theorospherical caps. These types of capes have a longer life and pressure tolerance than other types of caps.

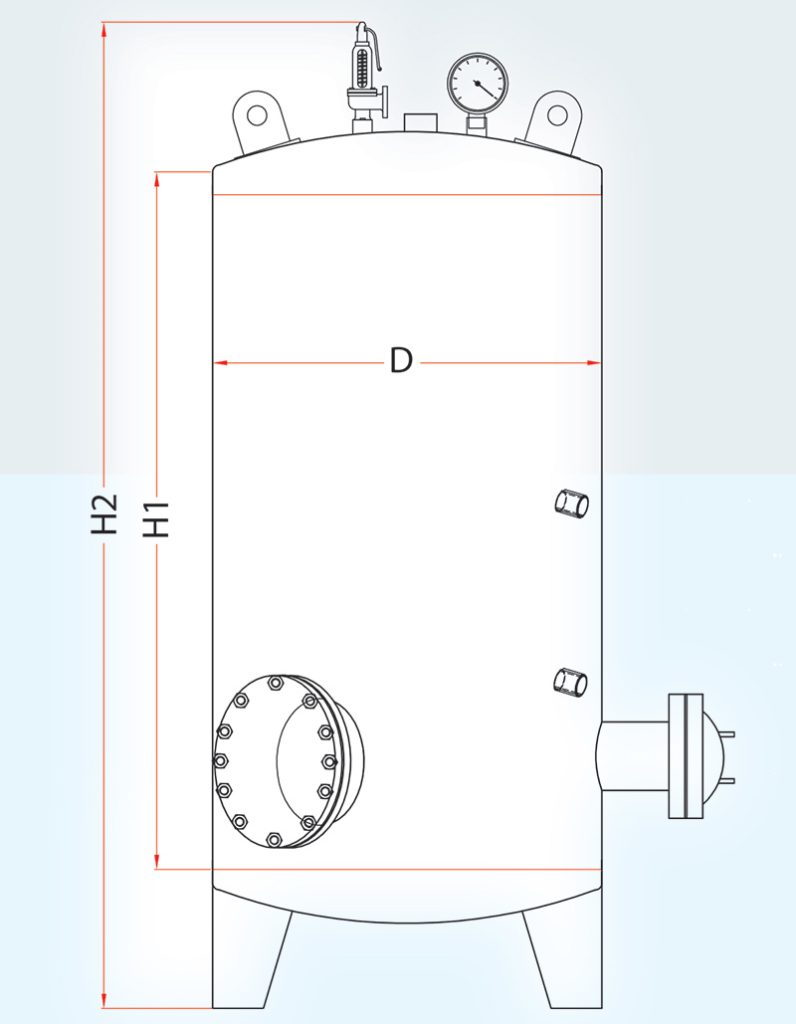

. Necessary bushings for hot water outlet, water inlet, thermocouple, drain, thermometer, safety valve and pressure gauge will be installed on the device (before painting)

. Each device has a hand-hole valve for capacities less than 2000Lit and a manhole for higher capacities.

. Welding of pressurized parts is done SAW and automatically, which provides the highest welding quality.

. Consumable electrodes are 7018,7010 which are used in accordance with PQR & WPS.

. Each device is equipped with two strong molds for carrying the device.

. Test pressure 1.65 times working pressure

. Steel used in making capes of 17MN4-DIN17155-Gr70 A516

. The copper coil used is based on the latest BS & ASME standards.

. After cleaning at least two layers of special epoxy inside the machine and outside it after zinc reach, oil paint is applied on the welding place.